|

|

|

You can get e-magazine links on WhatsApp. Click here

|

|

|

|

|

|

Cheddar Cheese: An ingredient for value-added dairy products

|

|

Wednesday, 25 January, 2023, 13 : 00 PM [IST]

|

|

Sivakumar S, Viji P C, Rekha Chawla, Nitika Goel, Venus Bansal

|

Milk and milk products offer a profitable segment for value addition particularly cheese having tremendous potential in the market. The Indian cheese market will reach $135.4 billion by the year 2024, growing at a CAGR of around 26% during 2019-2024. Cheddar cheese, originated in the English village of Cheddar in Somerset, is a comparatively hard, off-white, popular cheese due to its strong flavour and its use as an ingredient in various culinary dishes.

Cheddar cheese has high protein particularly casein content, which includes varying quantities of all necessary amino acids, fat, trace quantities of vitamins A, B2, B6, B12 and calcium contents which play an important role in providing balanced diet. Cheddar cheese, which is one of the varieties produced on a commercial scale in India, requires a lengthy ripening period of 4-12 months for flavour development, which increases the cost of the cheddar cheese.

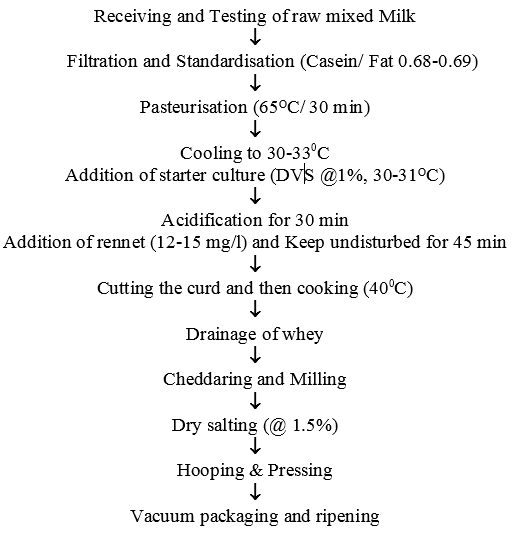

As per FSSA, 2011, ‘cheddar cheese’ means ripened hard-pressed cheese obtained by coagulating heated or pasteurised milk with harmless lactic acid producing bacteria cultures, suitable enzymes of non-animal origin or other suitable coagulating enzymes. The cheddar cheese have a coating of food grade waxes or wrapping of cloth or polyfilm. It shall have firm, smooth and waxy texture with a pale straw to orange colour without any gas holes. The general flow chart for the production of cheddar cheese is depicted below:

Preparation of cheddar cheese from mixed milk

Cheddar cheese powder, a variant of dehydrated cheese, is another emerging segment with increased usage worldwide, as cheddar cheese requires a long ripening period and refrigeration storage. Cheddar cheese powder has a long shelf life, is easy to transport, and can be used as a convenience and multifunctional ingredient in fabricated food products. Cheddar cheese powder properties are affected by the use of different raw materials, addition of ingredients, drying method and storage conditions. Cheddar cheese powder is sprinkled on popcorn, baked potatoes, and other dry snacks for a cheesy excitement or rehydrated and used in fillings. Cheddar cheese powder was prepared by combining melted cheeses, water, and emulsifying salt to create a homogenous and stable emulsion known as cheese feed, which was then spray-dried or tray-dried or vacuum-dried to obtain the final end-product for application in different food products.

Cheddar cheese is also used as an ingredient for manufacturing of processed cheese. As per FSSA, 2011, ‘Processed Cheese’ is obtained by grinding, mixing, melting and emulsifying one or more varieties of cheeses with the help of heat and emulsifying agents and may contain cream, butter, butter oil and other milk products. Processed cheese may also contain non-dairy ingredients not exceeding 1/6thof the weight of the total solids of the final product on dry matter basis.

Cheddar cheese making is a scientific art which further needs the balance between the fields of chemistry, technology, and microbiology of milk. Due to diversification prevailing in the current food habits, the use of latest technologies of processing necessitates the specific tailor-made functionalities in the commercial cheese products helpful to fulfil the consumers as well as entrepreneurs.

(The authors are from College of Dairy Science and Technology, Guru Angad Dev Veterinary & Animal Sciences University (GADVASU), Ludhiana, Punjab)

|

|

|

|

|

|

|

|

|

|