Bakery industry is one of the largest food processing segments in India. Consumers are demanding newer product options, and the industry has been experiencing fortification of bakery products in order to satisfy the growing appetite of the health-conscious Indian.

According to our market research, the India bakery market is lucrative and is expected to grow with a CAGR of over 8.30% during the forecast period 2018-2025 owing to constantly changing taste, health-consciousness.

As to meet these demands, bakery needs variety of raw material like wheat, maize and oats and requires a quantitative strategy as a remedy to the identified constraints. Rise in innovation of bakery product offerings, increase in per capita income of households, surge in consumer spending on food products will drive the market over the forecast period. Moreover, the consumers are more conscious than ever before, changing dietary habits and the movement towards healthy eating habits are few of the greatest influencers as well challenges of the India bakery industry.

Challenges in Industry

To address these challenges, there is need for accurate and timely forecasting of customer demand. There is a huge supply chain management gap in the Indian bakery industry. As the bakery products are highly perishable items with a shelf life of only 2 to 3 days, they need to be distributed within 40 hours of manufacturing.

The industry needs to have a strong distribution network including various middlemen and supply to reach every corner of the country. Apart from that, some of the other major challenges with the Indian bakery industry today are that there seems to be a hiking of raw materials prices, labour and production costs.

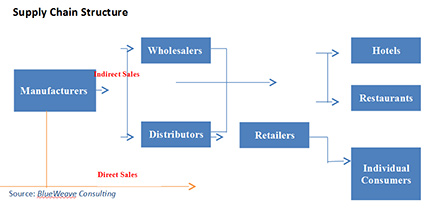

Indian bakery industry consists of direct sales and indirect sales. Indirect sales channel entails distribution of the product by manufacturer through various middlemen like wholesalers, distributors to the front-end sellers like retailers, hotels and restaurants. Direct sales consist of direct distribution of products by manufacturers to directly to the consumers.

Supply chain and demand forecasting enable manufacturers to understand their customers’ buying patterns and match with supply. In order to maximise the return on assets, most manufacturers resort to demand, forecasting and supply chain planning. Accurate forecasting and strong supply chain planning help the manufacturers to ensure that they get a real and complete picture of anticipated customer demand on a finished product level as well as supply.

Most of the respondents especially those with in-house bakeries found, it is difficult to plan and have steady forecasts. In-house bakeries were adopted by most Indian retailers in order to counter the delays and costs associated with outsourcing bakery product. Backward integration enables the retailers to forecast.

Outbound LogisticsThere is a need for every player in the Indian bakery industry supply chain to carefully plan and execute their activities, means the outbound logistics should be well organised to meet the needs of end-users. The supply chain needs to be controlled in every way; and it can be achieved such a way if every company makes proper decisions on both the supply and demand side.

The Indian supply chain needs to be organised in such a way that it is open to change. An integrated supply chain need not be rigid. The purchasing firms in this case bakeries or retailers should be in a position to have supplier databases and customer organisation databases. This will enable information on issues such as demand and costs of raw materials to assist in the planning and forecasting.

Supplier databases will also assist in establishing the lowest possible switching costs in cases where the situation demands for a switch in suppliers. Moreover, there is a need for investment into the industry supply chain in order to improve the liquidity. Indian government initiatives are required in the form of capital investment in order to push the operations of the bakery industry.

(The author is research director, BlueWeave Consulting)