Food additives are chemical substances that are added to foods to produce specific desirable effects, such as a certain taste, texture, appearance, or consistency in the final product. With increased processing of foods, additives are playing an important role in meeting the necessary quality standards with every production batch and have enabled efficient manufacturing across many food processing industries. Food additives prevent foodborne illnesses and enable transportation of food to areas that otherwise would not have been possible.

This article covers the types of additives, current trends in the dairy industry in India, and how standards employed by FSSAI (Food Safety and Standards Authority of India) aim to improve public health and nutrition and provide economic benefits to customers.

Types and Functions of Additives in the Dairy Industry

In general, food additives are classified into the following categories:

I) Nutritional Additives

II) Processing Agents

III) Preservatives

IV) Sensory Agents

i) Nutritional Additives

Nutritional additives are used to restore nutrients lost or degraded during the manufacturing of the product. It is essential to fortify certain foods to alter dietary deficiencies and increase nutritional value. Vitamins A and D are added to dairy products, vitamin B is added to flour, cereals, baked goods, and pasta, and vitamin C is added to fruit beverages, cereals, dairy products, and confectioneries.

Vitamin A is a common additive in the dairy industry. Although it is a fat-soluble vitamin that can be found in the fat portions of animals and is quite abundant in milk fat, the skimming process results in the loss of vitamin A. Hence, vitamin A is later added to replenish the amount that was lost. FSSAI has released the standards for the fortification of standardised, toned, double toned or skimmed milk. As per the FSSAI standards, the milk needs to be fortified with vitamins A and D at a level of 270 µg RE-450 µg RE per liter and 5 µg-7.5 µg per liter, respectively.

ii) Processing Agents

Emulsifiers are processing agents that are used to retain a uniform dispersion of one liquid in another, such as oil in water. The hydrophobic portion of the emulsifier dissolves in the oil phase, while the hydrophilic portion dissolves in the aqueous phase, thus forming a dispersion of small oil droplets. Therefore, emulsifiers ensure the uniform dispersion of oil-soluble flavour compounds throughout a product, preventing large ice crystal formation in frozen products such as ice cream.

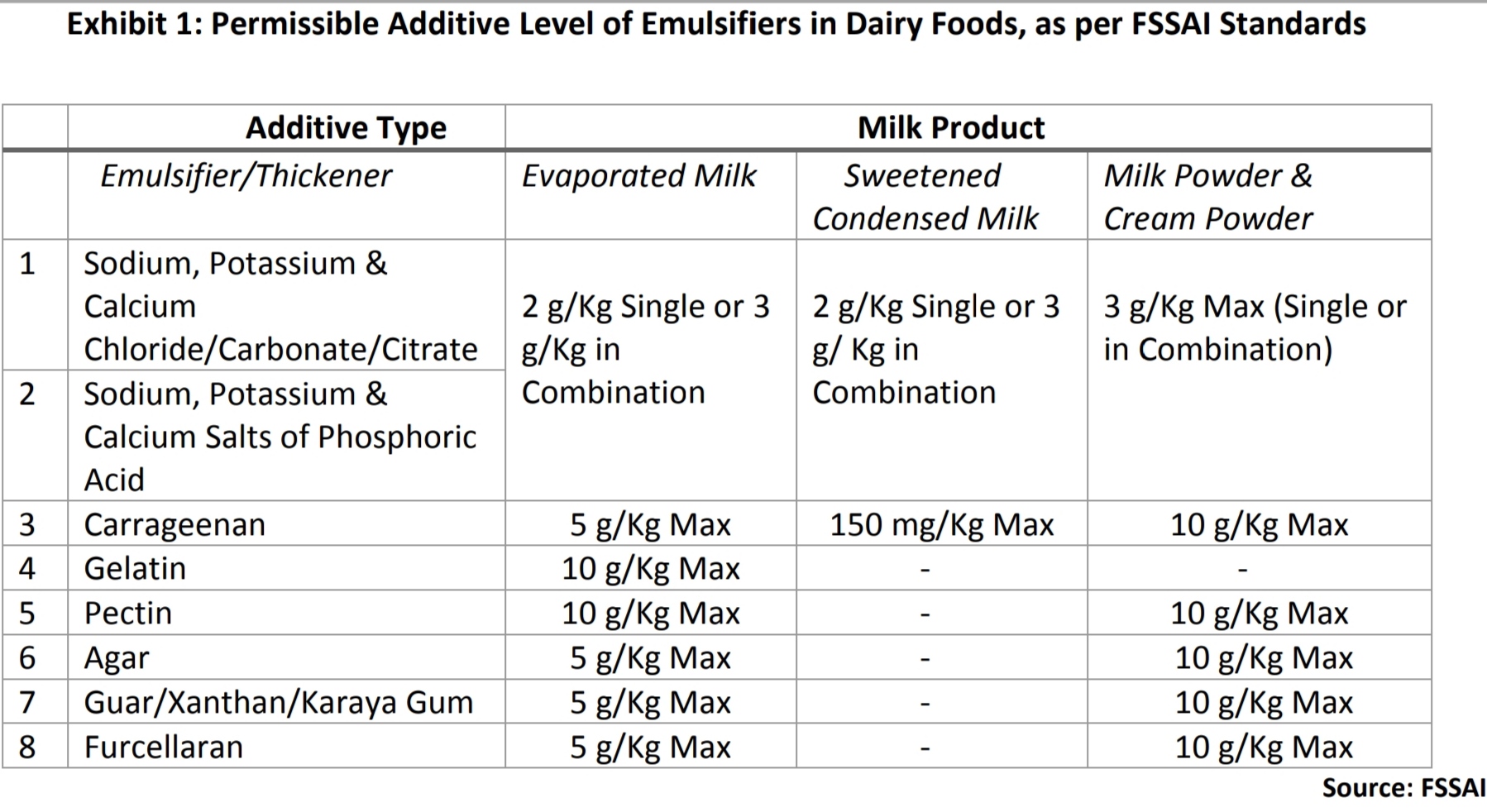

Additives with such stabilising properties improve the volume, evenness, and consistency of the final product. Exhibit 1 represents permissible levels of emulsifiers allowed in milk products, according to the FSSAI.

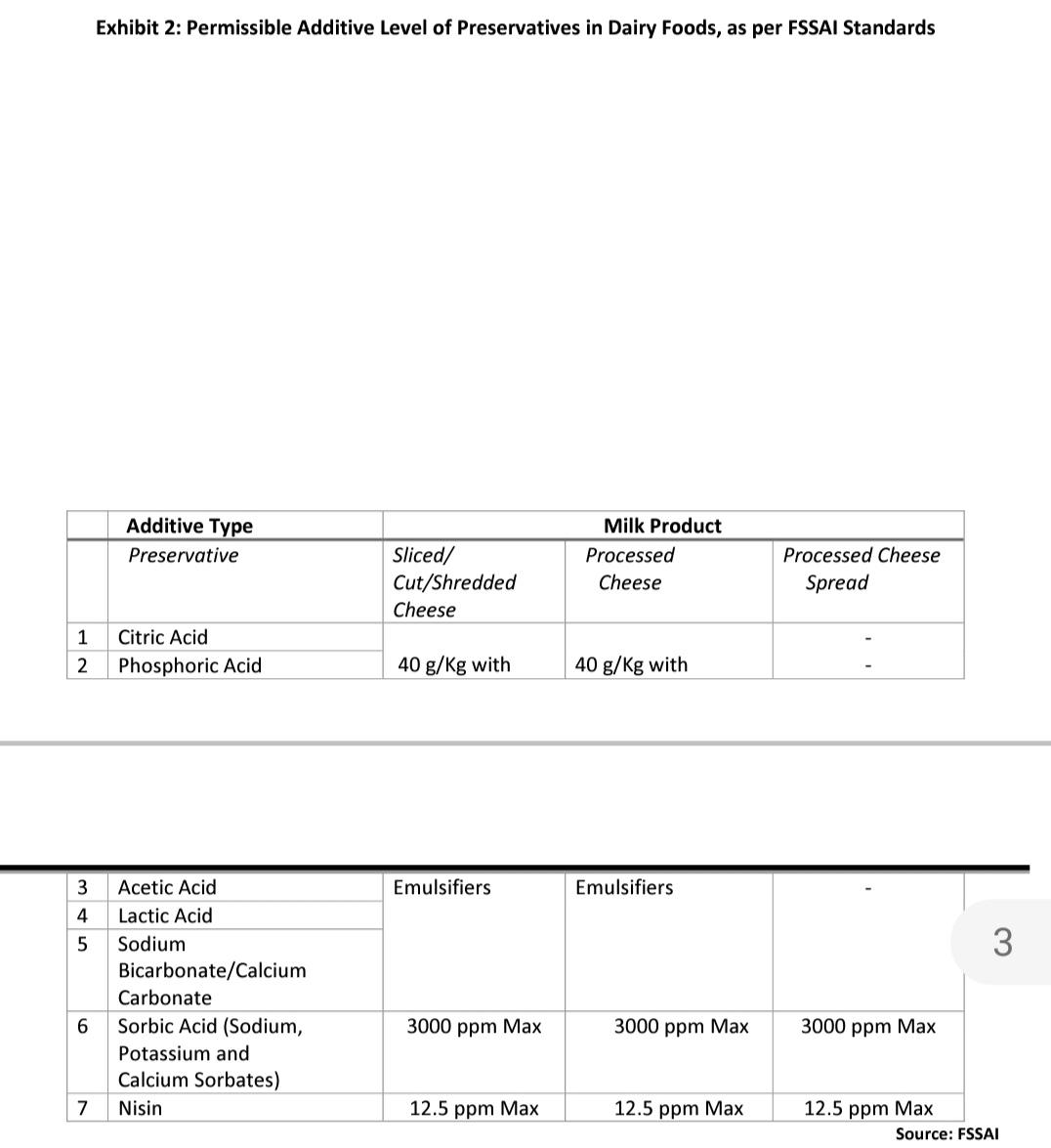

iii) Preservatives Food preservatives are categorized into two main groups: antioxidants and antimicrobials. Antioxidants are used in the food processing industries as a means to hinder oxidation and enhance flavor, aroma, and color. The oxidation of food products consists of adding an oxygen atom or deduction of a hydrogen atom from the molecules in the food. The products of these oxidation reactions that occur in fruits and vegetables like apples, bananas, and potatoes may lead to quality changes in the food and cause enzymatic browning. Among these antioxidants, there are reducing agents such as ascorbic acid (vitamin C) and agents that inactivate the enzymes, such as citric acid. Citric acid is used throughout the dairy industry, especially for cheese processing and production, as an excellent stabilizer. Antimicrobials are used primarily for preservation, to inhibit the growth of pathogenic microorganisms. Organic acids such as acetic, benzoic, propionic, and sorbic are used against microorganisms in products with a low pH. The growth of microorganisms is controlled by adjusting pH levels. In the dairy industry, milk products such as yogurts, cheeses, yogurt drinks, etc., primarily are produced with preservatives to avoid spoilage. For example, sodium benzoate and/or potassium sorbate are preservatives that inhibit mold growth and keep the product fresh.

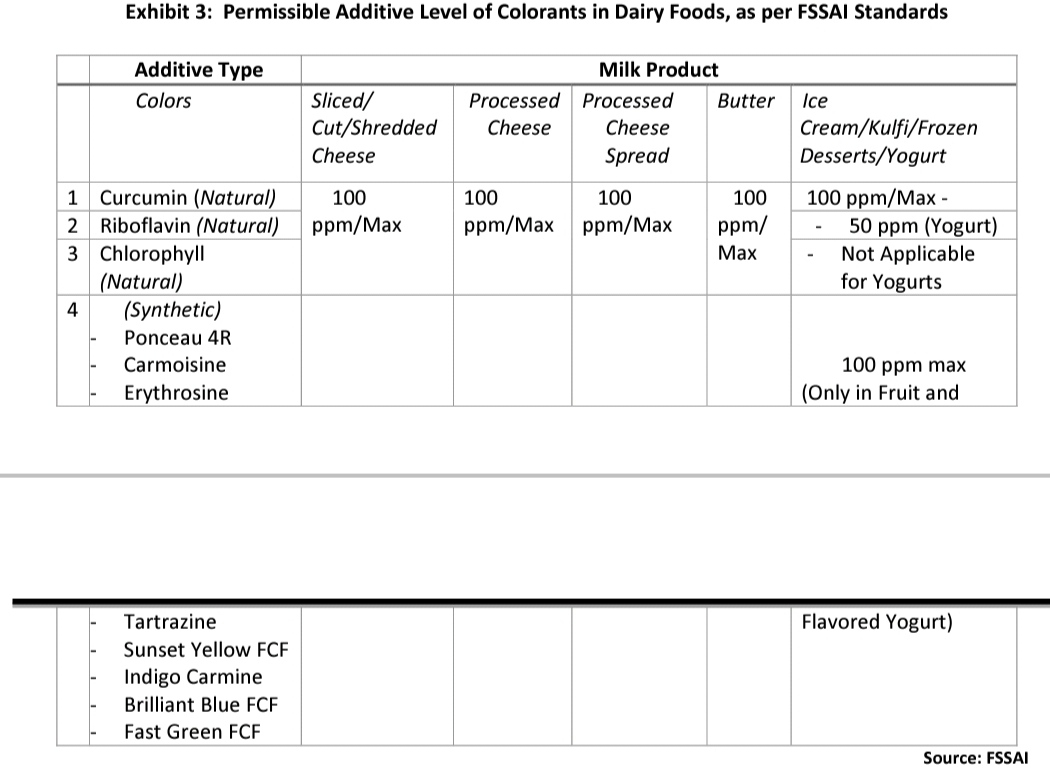

iv) Sensory Agents Sensory agents that are used in the dairy industry consist of colorants, flavoring agents, and sweeteners. Colorants are an important category of additives that bring out the sensory characteristic of food products, as they influence both the flavor and quality of the product. During processing, there could be degradation of the natural colors in the raw material; coloring agents ensure that uniform products are produced with the same intensity. Natural colorants are derived from plant, animal, and mineral sources, whereas synthetic colorants are primarily petroleum-based chemical compounds. Curcumin, for example, is a natural colorant extracted from turmeric. Synthetic colorants are not universally approved in all countries and usually undergo extensive toxicological analysis. Indigo Carmine and Sunset Yellow are common colorants used in yogurts and ice creams, as shown in Exhibit 3. Frost & Sullivan’s analysis indicates that in recent years, consumers have become more health-conscious and demand greater transparency in the ingredients that go into the product they consume. They are taking a greater interest in nutrition and examine food labels more carefully before making a purchase decision. Artisanal yoghurt brands in India have gained popularity because it doesn’t contain preservatives or artificial flavors, resulting in a natural taste from real fruit pulp. Low-fat milk or yoghurt-based drinks with high content of fruits and vegetables without any preservatives, coloring or artificial sweeteners have entered the market in recent years and garnered attention due to their unique selling points.

A flavor additive is a single chemical or a blend of chemicals of natural or synthetic origin added to food to enhance the natural flavor. In terms of consumer acceptance and marketing, the flavor of milk and milk products is a prime parameter. Dairy proteins may have flavor variations due to seasonal and regional milk supply patterns, and the addition of these products neutralizes off-flavors associated with these isolates and ensures a consistent base profile. For example, chocolate milk with 20% reduced sugar will not taste the same as the original version. Flavors have been developed to make up for the reduction in sugar and still deliver the rich and complete taste of the chocolate flavor by restoring the taste of the full-sugar original version. Flavored milk has not reached mainstream consumption in India. According to Frost & Sullivan’s analysis, Indian consumers are vowing to adopt healthier lifestyles and are actively seeking added benefits, so there is a rising focus on the addition of ingredients rather than their removal. Fortified dairy drinks that target specific health concerns should find demand. MNCs in India are looking to fortify their milk portfolio after the launch of healthier products, by introducing Greek yoghurts. With product innovations and expanding distribution channels, flavored dairy drink market is expected to grow in the coming years, which in turn will increase the demand for flavor additives.

What Next?

Food additives are subjected to rigorous toxicological analysis to assess their implications on health before their approval for use in the industry. With health hazards associated with the consumption of synthetic additives, Frost & Sullivan’s analysis indicates that there is a growing consumer demand for “no additive” food products or products with natural and bio-based additives. However, limited availability and the high cost of naturally sourced additives are still driving the market for synthetic food additives. With rising health and fitness trends, there is a rising consumer shift toward more natural and organic dairy products. With more emphasis on naturally made products, our analysis indicates that there have been increased R&D efforts to develop natural and bio-based additives and flavors.

(The author is consulting analyst, visionary science practice, Frost & Sullivan.

She can be reached at Srihari.Daivanayagam@frost.com)